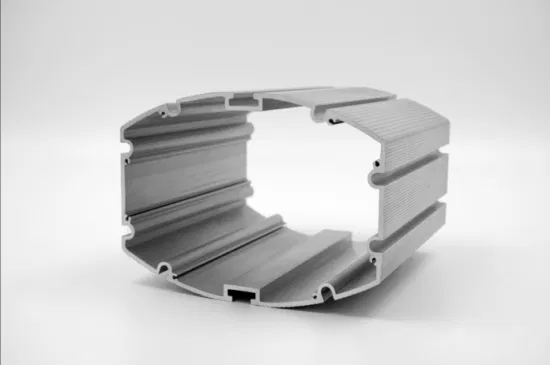

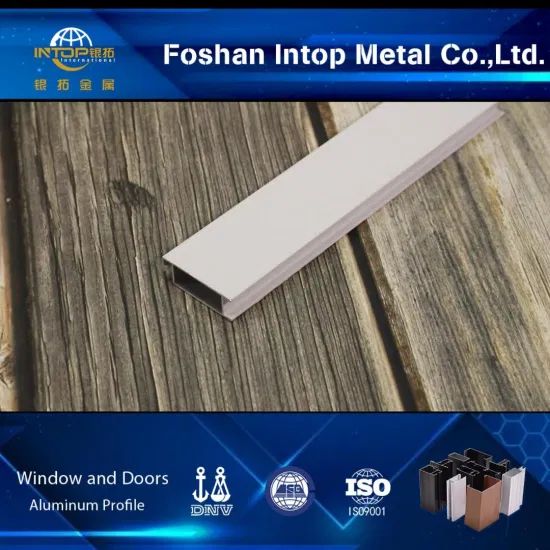

High Performance Aluminum Extrusion Profile Aluminum Frame Aluminum Profile

Overview Product Details Manufacturing Process Our factory owns complete production lines from aluminum log casting to t

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | group-44 |

| Window & Door Aluminium Profile | 60-90 Series |

| Alloy | Alloy |

| Surface Finishing | Custom |

| Alloying Ingredient | 6063 |

| Certification | ISO |

| Lead Time | 15-20 Days |

| OEM/ODM Brand and Logo | Yes and Do Small Profiles Insert |

| Supply Ability | 30000tons/Year |

| Accessories | Door Closer/Hinges/Roller/Handles/Locks/Screws/Bli |

| Inspection | 100% QC Testing |

| Deep Process | Punching Driling Precison Cutting CNC |

| Main Market | South Africa/Southeast Asia/South America |

| Payment Term | 30% Tt Deposit 70% Balance / LC |

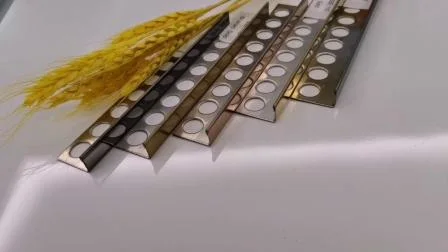

| Color | Silver/Champagne/Bronze/Black |

| Thickness | 0.7/0.8/0.9/1.0mm etc |

| Length | 2.5m/3m/5m/5.8m/6m |

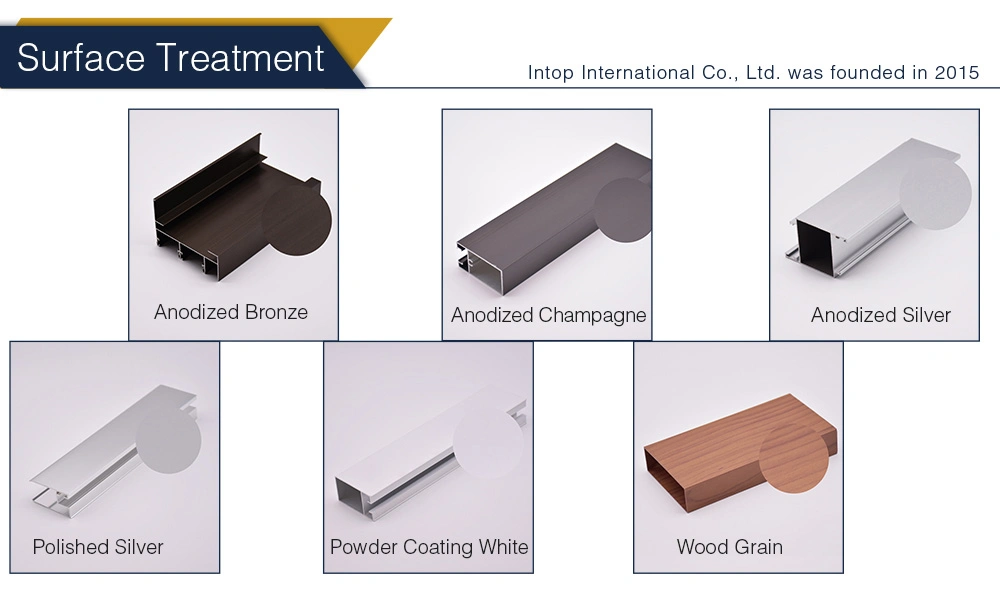

| Surface Treatment | Anodized/Powder Coated/Polished/Woodened |

| MOQ | 300kg/Size |

| Feature | High Durablity, Anti-Corrosion, Weather Resistance |

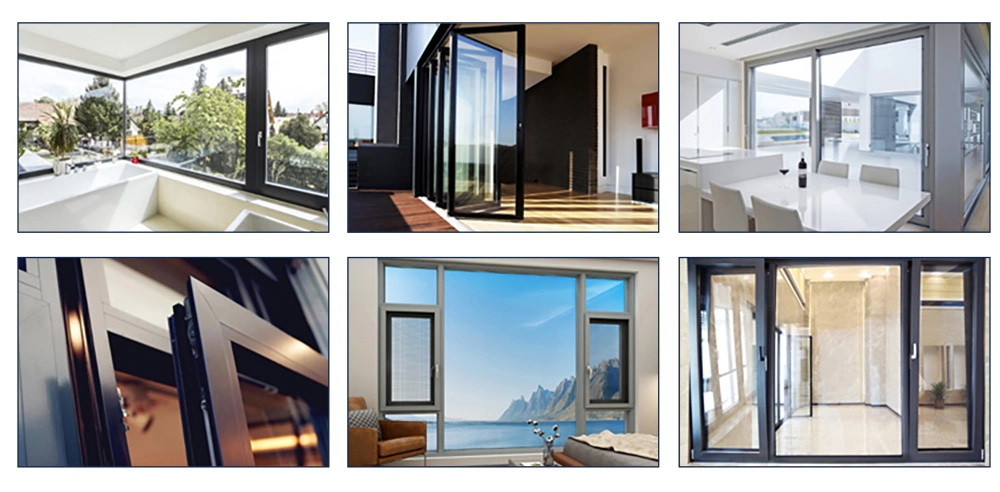

| Application | Door & Window/Building & Construction |

| Transport Package | Protective Film+Heat Shrink Film |

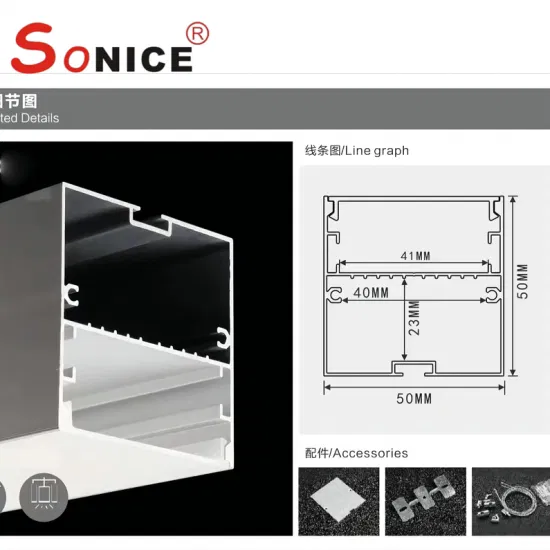

| Specification | Hollow profile, Non-Hollow profile |

| Trademark | Intop |

| Origin | Guangdong |

| HS Code | 7604210000 |

| Production Capacity | 30000tons |

Product Description

| China High Quality 6063 Aluminum Extrusion Profiles | ||||||

| Alloy&Temper: | 6063 | T4/T5/T6 | ||||

| Certificate: | ISO9001:2008 | PVOC | ||||

| Surface finish: | Mill finish | Anodizing | powder coated | Wood grain | Polished | sand blasting |

| Anodizing: | Silver/champagne/bronze/black. Anodizing thickness of 10um | |||||

| powder coating: | Many color choices, Powder coating thickness 40um-120um. | |||||

| Wood grain: | Heat transfer printing paper for making different textures of wood grain. | |||||

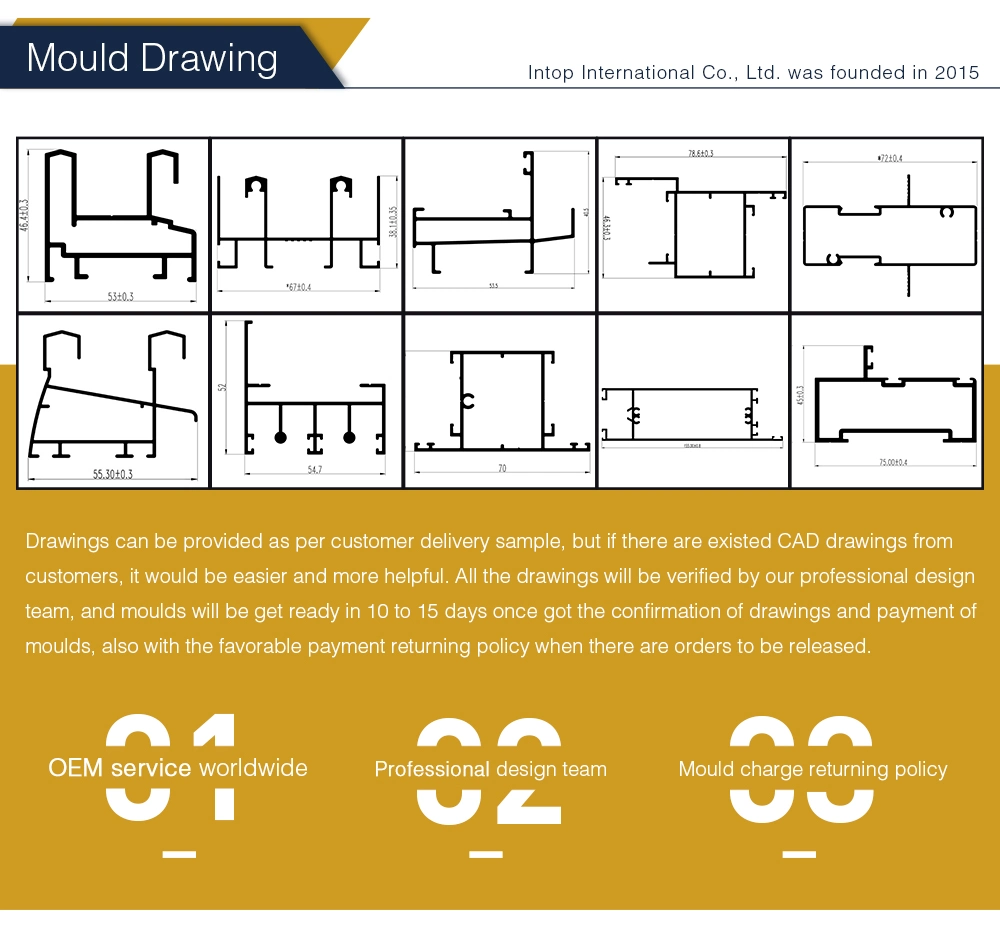

| OEM service: | Die making as per customers' drawing, scan the cross section as per delivery samples. | |||||

| Packing Details: | 1. Protective Film + Heat Shrink Film 2. Kraft paper 3. EPE Foam for Each Piece + Heat Shrink Film | |||||

Foshan Intop Metal Co., Ltd. was founded in 2015, located at Tian'an centre, Jihua Dong Road, Nanhai District, Foshan City, Guangdong Province, China. Foshan is well-known for construction and decoration materials like aluminum profiles, stainless steels, ceramic tiles and furnitures. Our head office is about 50 minutes' drive from Guangzhou Baiyun International Airport and 25 minutes' drive from Guangzhou South High-speed Railway Station, enjoying a good geographical location.

Our factory owns a vertical auto powder coating spraying production line, a horizontal anodizing production line, ten extrusion lines for different aluminum log diameters, with annual production over 30000 tons.The main products of our company are metallic construction materials, including aluminum profiles, aluminum composite panels, and doors/windows accessories like hinges, rollers, blind rivets, fesiner lock, corners, aluminum handles, door lock body, door closer, weathering strip, rubber PVC grain, window pile brush, tinted glass and reflective glass.We offer on line order checking service by video, and inspection report for every purchase order to track and guarantee the aluminum profiles you bought. Quality InspectionMore ProductCertificationsQ1: Can I visit your factory?

A: YES, welcome to visit us, our factory is located in non-ferrous industrial base, qingchen district, qingyuan city, guangdong, China. We would be pleased to pick you up from Baiyun airport or Guangzhou Nan high-speed train station or your hotel address in Guangzhou.

Q2: How to ensure the quality of aluminium profile I purchased?

A: We have professional inspection team to check the quality, starting from mill finish profiles extrusion, our QC will pick out any potential inferior profiles with mechanical lines, then for anodizing or powder coating etc. When the order is finished and ready for shipping, testing report will be done by QA for PASS.

Q3: How long it takes to finish the order?

A: Our production capability per month over 2000 tons, it takes about 20 days to get ready for a 40HQ container ready. But for the first new order, as the new moulds are needed to be created and tested normal, would last a month or so.

Q4: What is the payment terms?

A: Usually we prefer T/T deposit and balance payment against B/L copy, and L/C is also very common.Contact&Get a quote