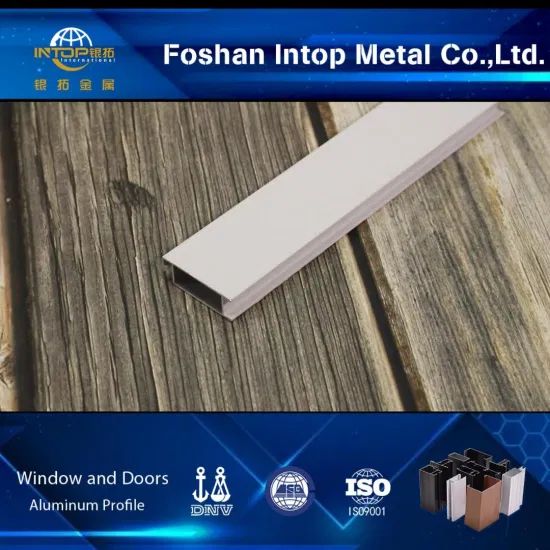

Anodized Brush Wardobe Door Aluminum Profile Glass Cabinet Frame Aluminum Extrusion Profile

Package Size 30.00cm * 20.00cm * 21.00cm Package Gross Weight 1.000kg Products Description

Send your inquiryDESCRIPTION

Basic Info.

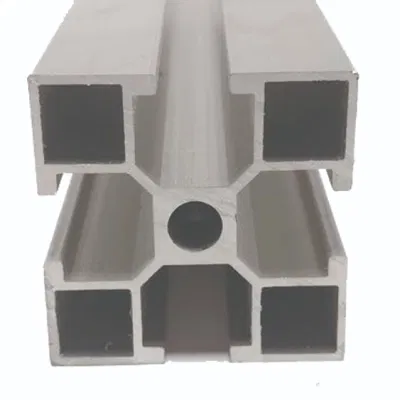

| Shape | Square |

| Grade | 6000 Series |

| Temper | T3-T8 |

| Window & Door Aluminium Profile | 60 Series |

| Alloy | Alloy |

| Surface Finishing | Anodic Oxidation |

| Alloying Ingredient | 6063 |

| Certification | CE |

| Polished Aluminum Profile | Mechanical Polishing |

| Surface Treatment | Brush |

| Transport Package | Film and Plastic Bag |

| Specification | 20MM |

| Trademark | COLIKE |

| Origin | China |

| Production Capacity | 50000 |

Packaging & Delivery

Package Size 30.00cm * 20.00cm * 21.00cm Package Gross Weight 1.000kgProduct Description

Products Description

| Item Name | Anodized/Powder Coat Aluminum Extruded Profiles for wardrobe and glass cabinet |

| Material | 6061/ 6063 |

| Temper | T4,T5,T6 |

| Surface Treatment | Powder coating, Electrophoresis, Mill finish, Anodizing, Wood grain. |

| Color | Brush Gold,Gray, champagne, wooden color or customized by your requirements. |

| Usage | Windows, doors, curtain walls, rails, decoration profile. |

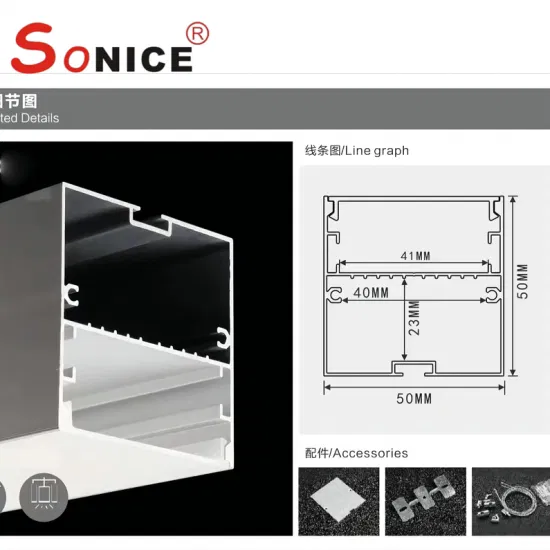

| Thickness | 1.General profiles thickness: 0.8mm-1.4mm2.Anodizing protection thickness: 8-12 micron3.Normal powder coated thickness: 60-100 micron |

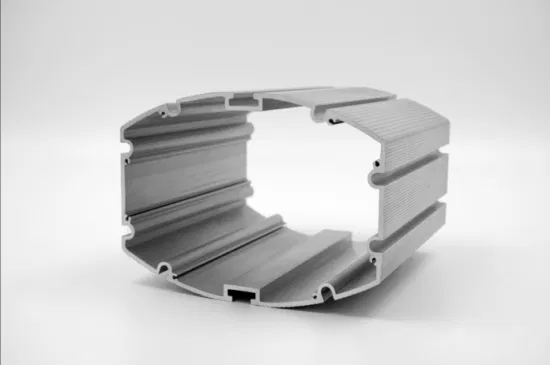

| Shape | Square, angle, flat, hollow, oval, triangle, U-profile, L-profile, T-profiles, H-profiles or customized available. |

| Length | General lengths 3m - 8m. Or can be customized to your requirements. |

| Deep Processing | Cutting, drilling, punching, bending etc. |

| 3D Design | 1. Designers in design and development department2. Auto CAD, 3D, PDF, JPEG etc. |

| Engineering& Tooling | 1. 8 Engineers in Mold Shop.2.Use high tonnage extruder, Wire EDM, CNC, Drilling machines etc. |

| Quality Control | 1. Inspection at Site.2. Inspection Before Shipping.3. Testing Machine. |

Related Products