Aluminum Aluminium Profile for Metal Sliding Window Door and Casement Awing Glass Window

1. Description: Aluminum Aluminium Profile for Metal Sliding Window/Door and Casement/Awing/Glass Window 2. Alloy temper

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | RA-038 |

| Window & Door Aluminium Profile | 90 Series |

| Alloy | Alloy |

| Surface Finishing | Powder Spraying |

| Alloying Ingredient | 6063 |

| Certification | CE, SONCAP, ISO, CIQ, RoHS, TUV |

| Polished Aluminum Profile | Chemical Polishing |

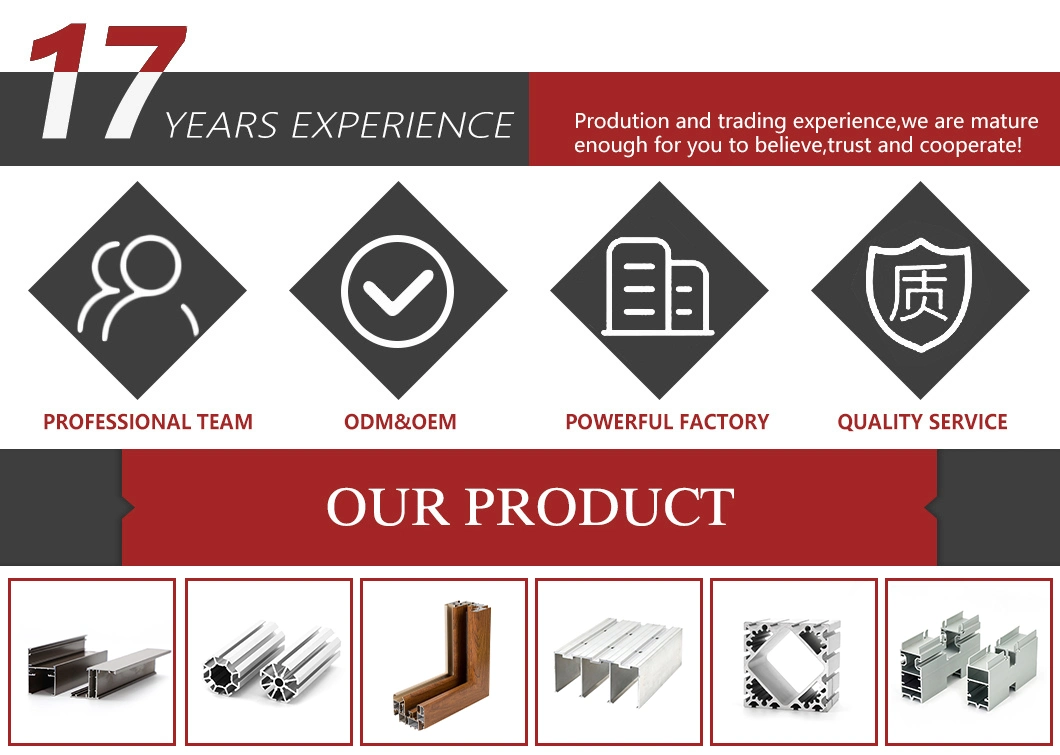

| Export Experience | 17 Years |

| MOQ | 200kgs |

| Press Lines | 45 Press Lines |

| SGS Test | Yes |

| Factory and Export | Directly |

| Deep Processing | Yes |

| SGS Inspection | Yes |

| Qulaity Control | 6s Quality Control |

| OEM/ODM | Yes |

| Quality Guarantee | Over 15 Years |

| Price Competitive | Yes |

| Free Mould | Yes |

| Paint Thickness | Over 80um |

| Anodized Thickness | Over 10um |

| Max. Width | 500mm X 500mm |

| Transport Package | Export Standard Package |

| Specification | ISO9001 EN755 GB5237-2008 |

| Trademark | Reliance Aluminum |

| Origin | China |

| HS Code | 7604210000 |

| Production Capacity | 120, 000tons/Year |

Product Description

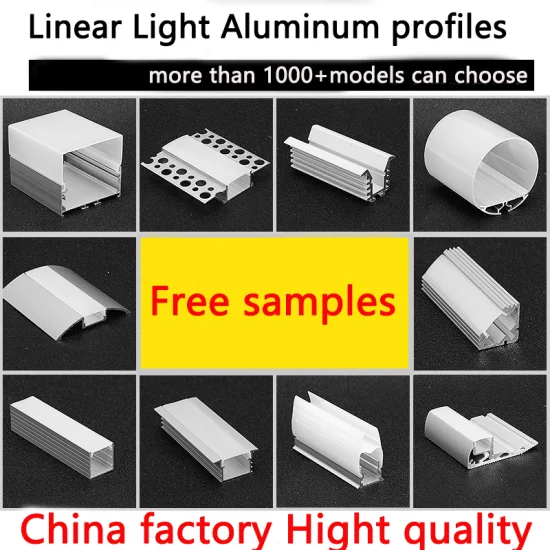

1. Description: Aluminum Aluminium Profile for Metal Sliding Window/Door and Casement/Awing/Glass Window

2. Alloy temper: 6063-T6; 5083-H112; 6061-T6/T651; 6082-T6/T651; 6351-T6; 7075-T6

3. Standard: EN755, ASTMB221, DIN Standard

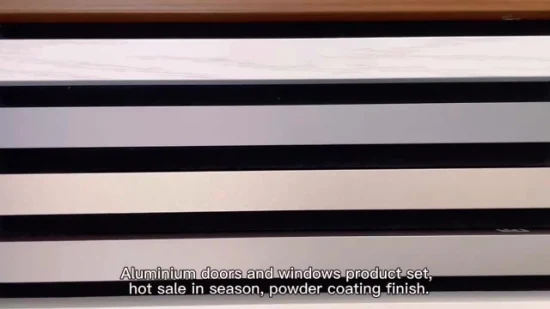

4. Surface treatment: Mill finish; Anodizing; Powder coated, Brushed.

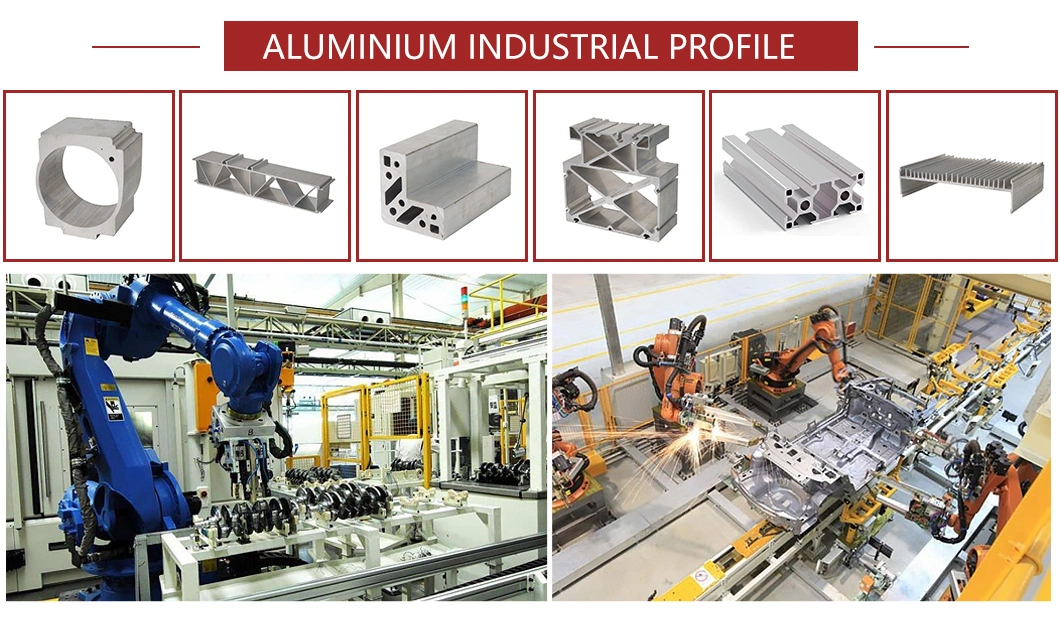

5. Application:Window, door, curtain wall, decoration ;Car; Aerospace; Ship; Armarium; Industrial equipment; And etc.

6. Advantage:

1) Pure 99.7% aluminum materials without any scrap used

2) OEM welcome, we can design and cut die to meet customer's special demand

3) Wonderful surface treatment, we can meet customers required on surface

4) Strictly quality control process assured higher quality.

5)Hard alloy longer life span

6) Packing safety and convenient.

| RELIANCE ALU PRODUCTION RANGE | ||||||||

| ALLOY | 6060 | 6063 | 6061 | 6082 | 6005A | 7075 | 2024 | 2014 |

| TEMPER | T5/T6 | T5/T6 | T6/T6511 | T6/T6511 | T5 | T6/T6511 | T4/T6 | T4/T6 |

| STANDARDAPPLY | EN755/DIN | GB5237-2008EN755-3/DINASTMB221AMS-QQA-4574 | GB6892-2008ASTMB221AMS-QQA-4574 | GB6892-2008ASTMB221AMS-QQA-4574 | GB6892-2008ASTMB221AMS-QQA-4574 | GB6892-2008ASTMB221AMS-QQA-4574 | GB6892-2008ASTMB221AMS-QQA-4574 | GB6892-2008ASTMB221AMS-QQA-4574 |

| CERTIFICATION | SGS /TUV - ISO9001:2008 | |||||||

| SURFACETREATMENT | Mill finish | Clearn anodized | Matt anodized | Chemcial polished | Machinery Polish | Brushed | PVDF Coating | 3D Wooden Paint |

| COLOR | Clearn / MattAnodized | Silver, bronze, champagne, titanium, nickel, golden yellow, etc. | ||||||

| The anodized film thickness is over 10um | ||||||||

| Chemical/Machinery Polished | Silver, bronze, champagne, titanium, nickel, golden yellow, etc. | |||||||

| The anodized film thickness is over 5um | ||||||||

| Powder coating | White, Black, Grey,Green, Blue, Yellow , Red and etc. | |||||||

| The powder coated thickness is over80um. | ||||||||

| Wood Grain | 1.USA 3M and Italian MENPHIS transfer printing paper. | |||||||

| 2. AKZO NOBEL INTERPON D1010(10 years warranty): Australia ceder, Bush cherry, Chest nut, Jarrah I, Jarrah II, Western red ceder, etc. | ||||||||

| 3. AKZO NOBEL INTERPON D34(5 years warranty): Bush wood, Western red, Jarrah, Snow gum, etc. | ||||||||

| Electrophoresis | Silver, nickel, golden yellow, black, champagne, etc | |||||||

| Brushed | Silver, nickel, golden yellow, black, bronze, etc | |||||||

| PVDF Coating | White, Black, Grey,Green, Blue, Yellow , Red and etc. | |||||||

| 3D Wooden Paint | Solid wood handle 3D wooden paint, White, Black, Grey,Green, Blue, Yellow , Red and etc. | |||||||

| DEEP PROCESSING | 90degree, 45degree and any degree Cutting, punching, drilling, bending, weld, mill, CNC, etc. | |||||||

| Window/door/fenster | Sliding, awinging, casement, thermobreak window/door | |||||||

| Aluminum with glass | Clearn float, lamited, tempering, Low-E Coated glassess. | |||||||

| OEM | Customized aluminium profiles are available. | |||||||

FAQ For Saving Your Precious Time!

Q1: What's the thickness for anodizing film? Can you do 15um?

A: Our normal thickness is over 10 um. Yes, we can do 15um and above.

Q2: What color you can do for powder coating?

The thickness for powder coating film?

A: We can do any color for powder coat as long as you can provide the color sample. Our normally powder coating thickness is 60-100um.

Q3: What color you can do for wood grain?

A: Our most popular colors are Western Red Cedar, Australia Cedar, Jarrah I, Jarrah II, Chestnut, Bush Cherry, Bush Wood, Western Wood, Snow Gum, etc. If you need any other colors, we can do according to the color samples you provide.

Q4: How's the weather resistance for wood grain finish D1010?

A: (1). Powder: Akzo Noble Interpon D1010.

(2). Wood grain film: Italian Menphis.

(3). Standard complied: American AAMA Standard.2603

(4). UV test:1000 hours.

(5). Salt spraying test:1000 hours.

(6). Normal weather: 10 years color guarantee.

Q5: What certification do you have? What's your standard?

A: We have ISO certification. Our standard is DIN, AAMA, AS/NZS, China GB.

Q6: What's the delivery time for samples and mass production?

A: (1). 2 weeks to open the new moulds and make free samples.

(2). 2-3 weeks after receipt of deposit and confirmation of the order.

Q7: Can you do deep processing and fabrication?

A: Yes, we have deep processing line in our factory, we can do cutting, drilling, punching, welding and deep fabrication.

Q8: Can you provide special export packing and loading?

A: Yes, we can follow end customers required for special packing and loading, and we have experienced engineer team to design and improve your idea.

Q9: What's your Quality Control Plan?

A: We have strictly 5S quality control plan in our factory, 1S is Incoming materials quality control, 2S is Production line quality control, 3S is Packing quality control, 4S Warehouse quality control and 5S loading quality control plan. We can avoid the Inferior quality issues our factory.

Related Products

-

![Customized 6063 Italy Style Cabinet Door Profiles Anodized Aluminium Doors Windows Profiles Price Per Ton]()

Customized 6063 Italy Style Cabinet Door Profiles Anodized Aluminium Doors Windows Profiles Price Per Ton

-

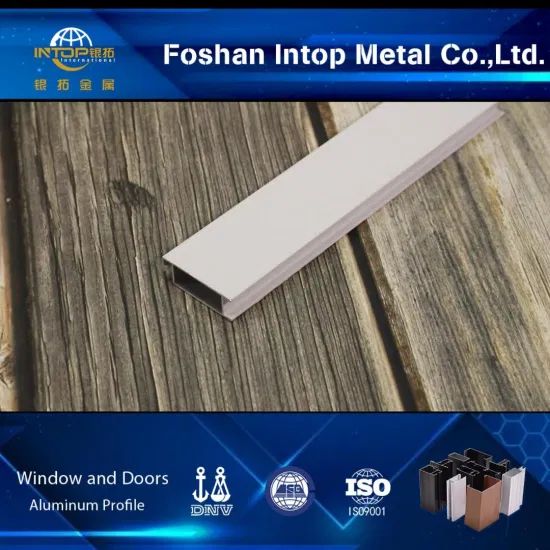

![Factory Sale Aluminum Profile for Aluminium Window and Door]()

Factory Sale Aluminum Profile for Aluminium Window and Door

-

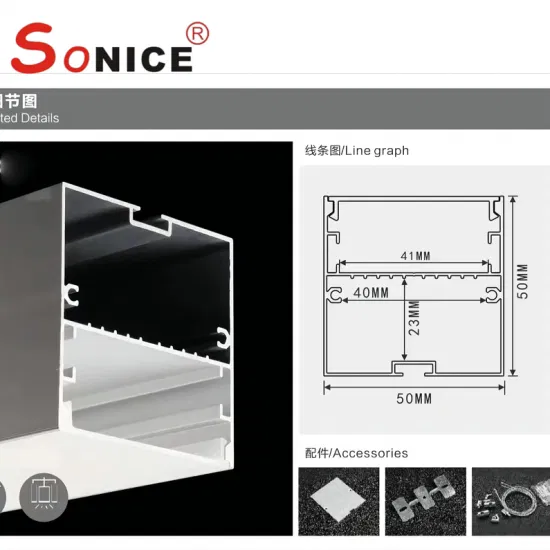

![Cabinet Light with SMD 2835 Flexible LED Strip U Shaped Channel Housing Aluminum Alloy Extrusion LED Profile Light]()

Cabinet Light with SMD 2835 Flexible LED Strip U Shaped Channel Housing Aluminum Alloy Extrusion LED Profile Light

-

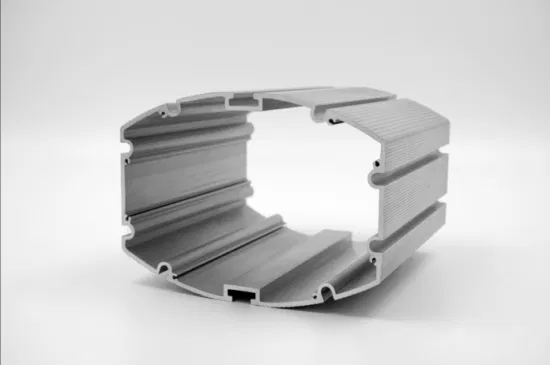

![Aluminium Profile for Window Door and Roller Shutters]()

Aluminium Profile for Window Door and Roller Shutters